Portfolio of Projects

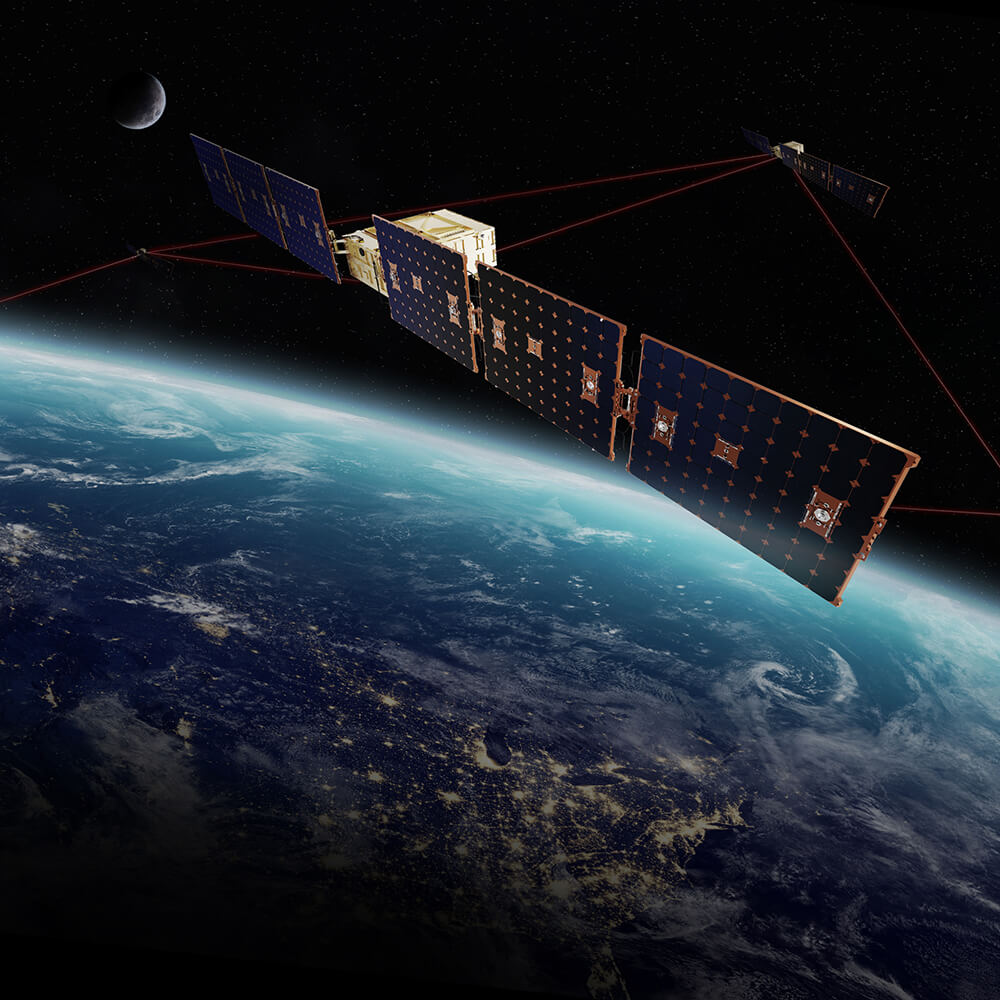

SDA's Tranche 0 Transport Layer - Terran Orbital

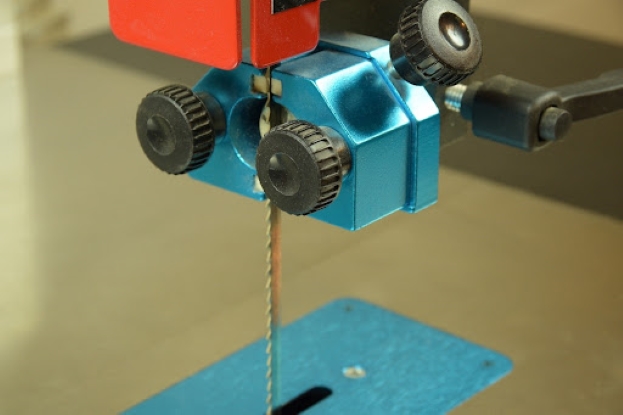

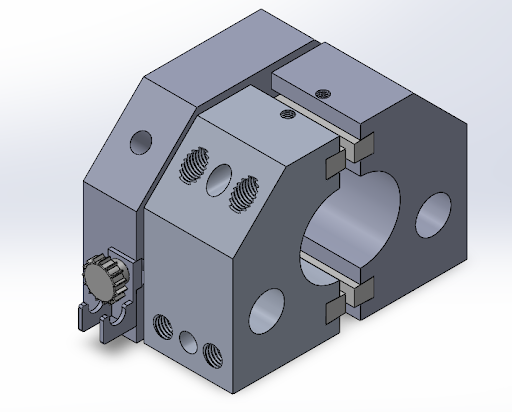

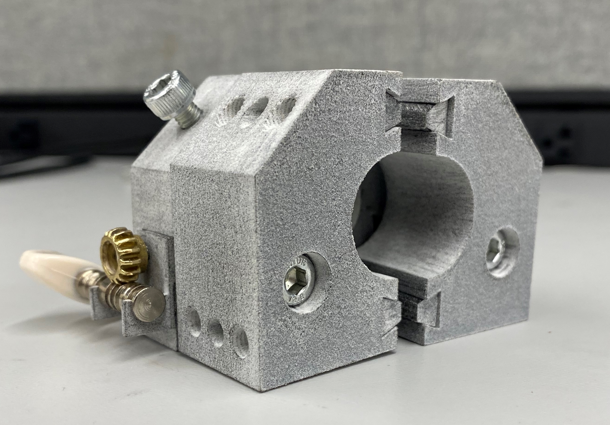

Bandsaw Blade Guide UX Design - Laguna Tools

Two-Legged Walker - UCI

Golf Ball Launcher Design and Manufacturing Project - UCI

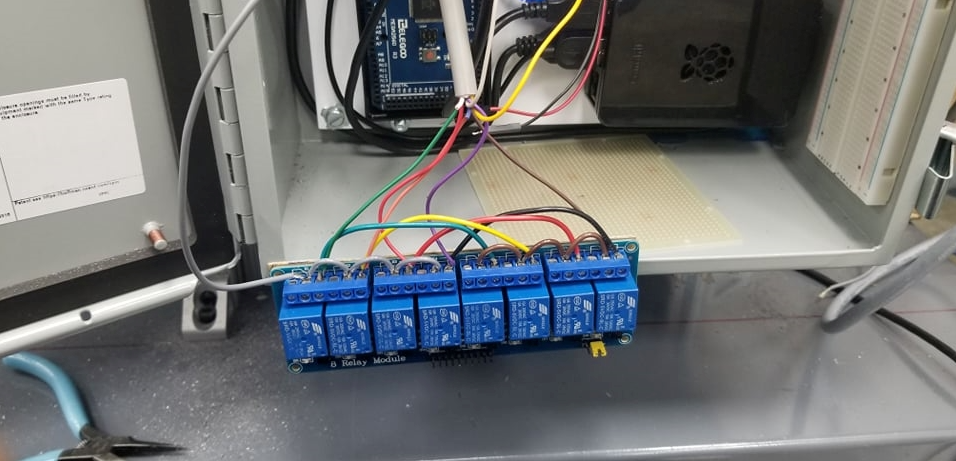

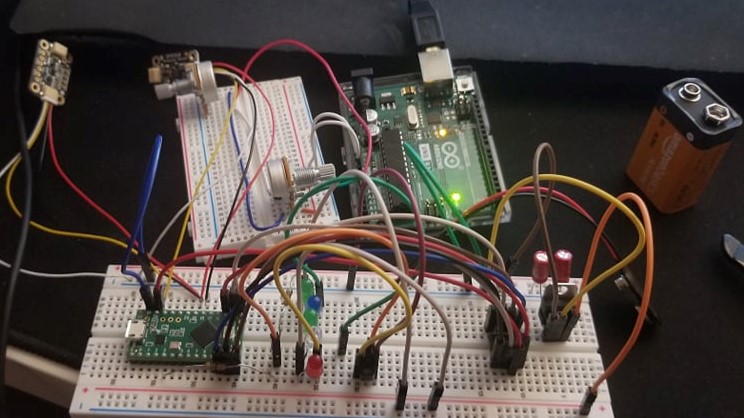

Automated Rotary Machine - Bal Seal Engineering

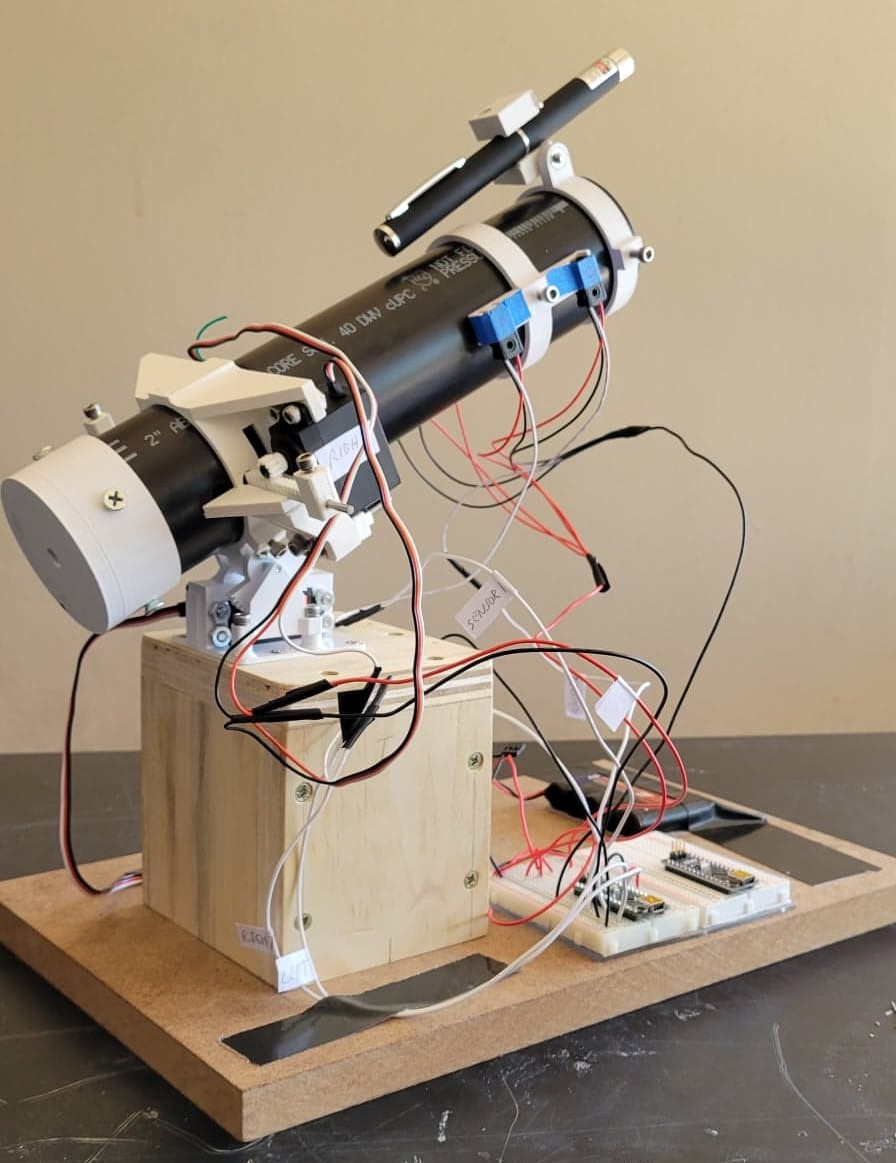

Solids & Liquids Rocket Project - UCI

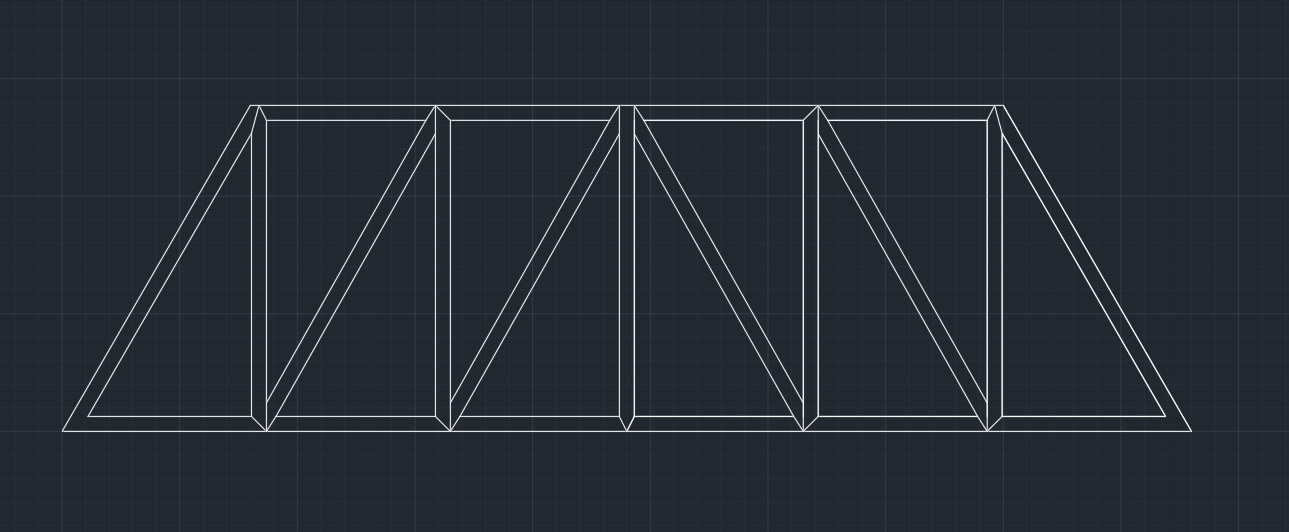

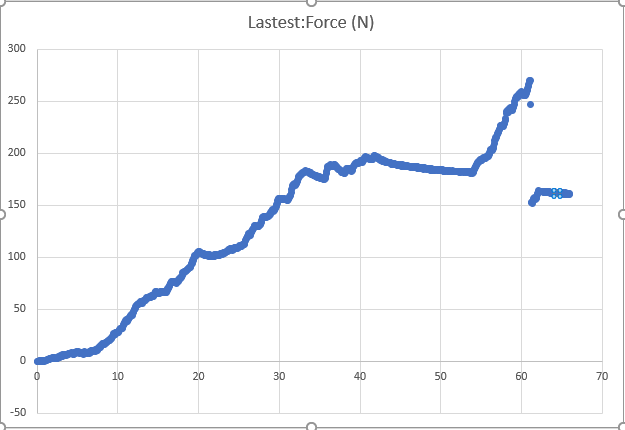

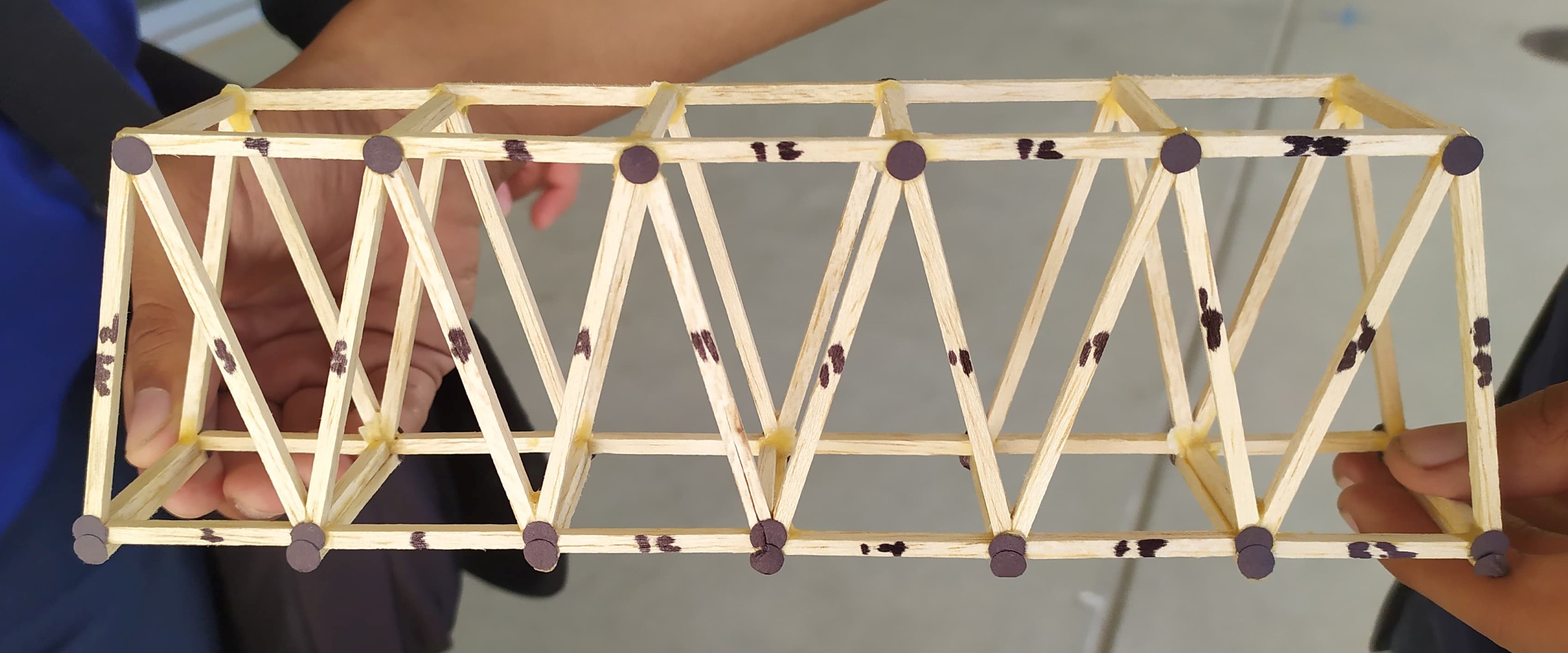

Yosemite Balsa Wood Bridge - UCM